DPT-Netherlands BV is specialized in processing (Profiling) flaking rolls.

Since 2015, DPT-Netherlands BV has been in possession of a fully automatic fluting machine, designed according to the latest wishes and innovations and completely under its own management. Together with Rodomach, the best in automation and robot technology, A.J. te Riele Vaassen MT built a machine that will prove its performance well into the future.

The tR810 has a capacity for rollers with a diameter of 810 mm, a length of up to 3000 mm and a weight of up to 6’500 kg. The speeds for profiling these heavy rolls reach far above 22 m/min and 105 m/min in the return.

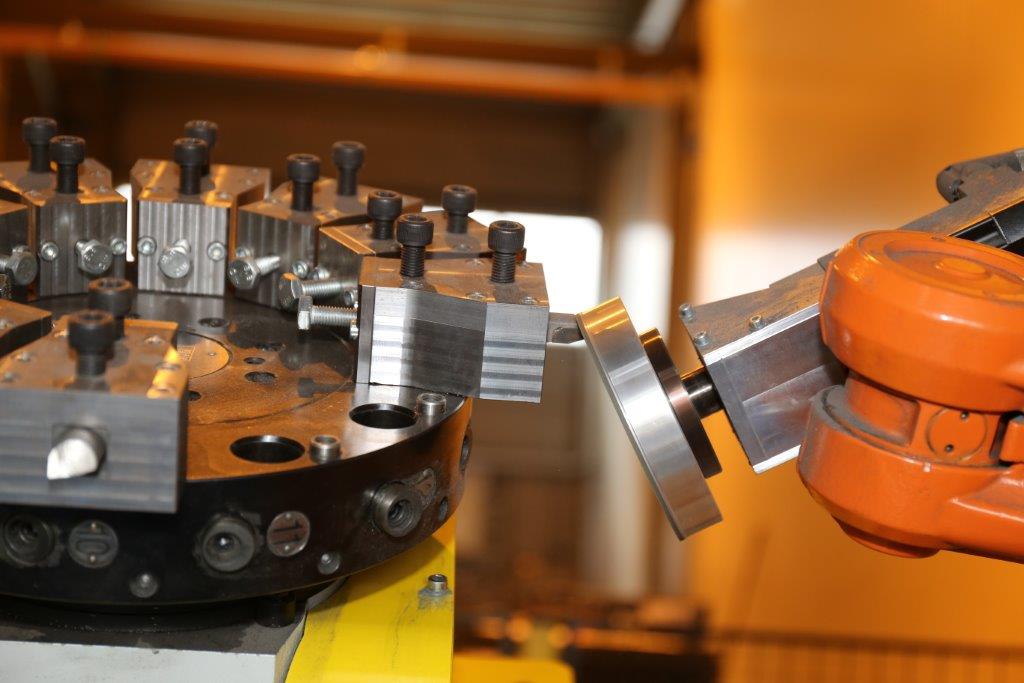

A carousel with 12 cutting steels ensures frictionless continuous processing of the roll. The speed and number of chisels used depend on the hardness and wear resistance of the material from which the roll is made. When the 12 chisels in the carousel are worn out, they are sharpened by a robot and profiling can continue from where it stopped.

Educations